The use of slaves in making has attracted careful attention from scholars of North American material culture, for example Catherine Bishir’s Crafting Lives (2013), and Glenn Adamson’s Craft: An American History (2021). We also have decades of fine scholarship on the use of enslaved West African ironworkers in colonial North America. The importance of enslaved blacksmiths is well established and reflected in major museum collections. The brutal lives and deaths of slaves at iron foundries and iron ore mines have been documented, including their exposure to heavy metal toxins. However, there is comparatively little written about workers of non-ferrous metals.[1]

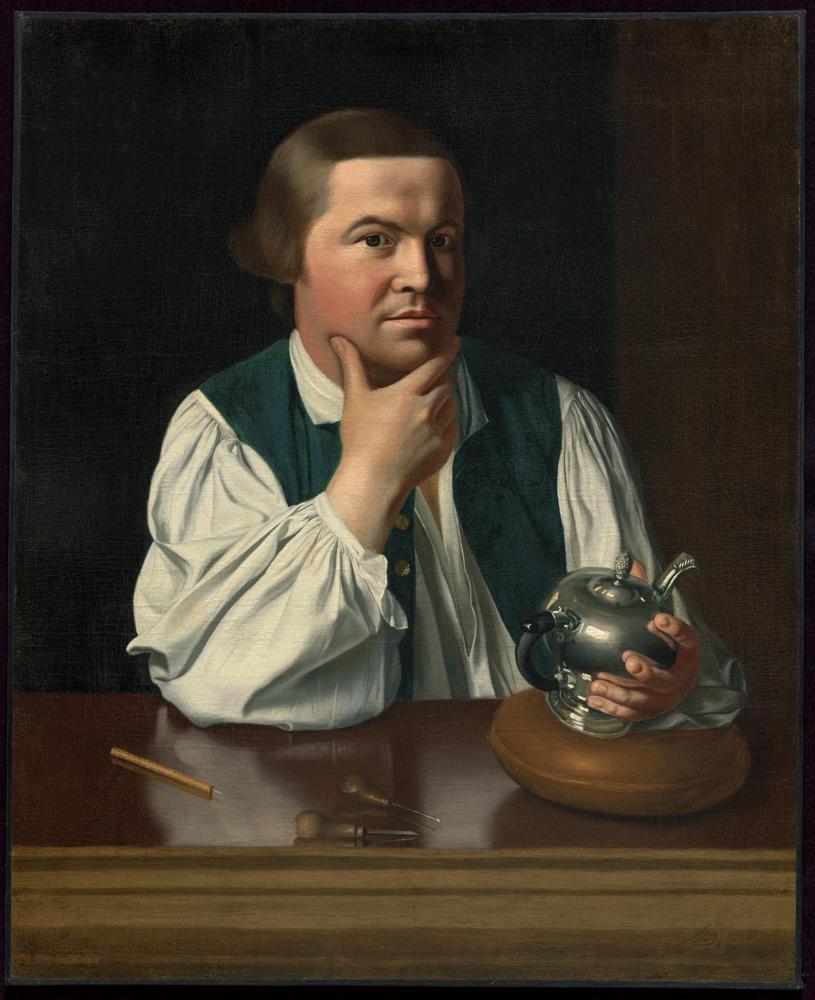

In Bishir’s detailed study of New Bern, NC, the silversmiths were all free, including the literally named Freeman Woods. Adamson paints on a far broader canvas. He introduces us to Native American silversmiths, such as Slender Maker of Silver, and reminds us that “When we are faced with an 18th-century teapot or high chest in a museum, it is usually impossible to know whether or not it was made partly with enslaved labor.” Adamson is certainly referring to a silver teapot: He begins his book with a portrait of Paul Revere (Boston MFA 30.781), painted in 1768 holding in his left hand a silver teapot that he has crafted, not unlike Agatho. Like Agatho, too, Revere is shown with the tools of his trade, with which he is about to decorate and engrave the teapot.[2]

A coffeepot crafted by Revere just a year after Copley painted his portrait is in the Yale University Art Gallery (2016.158.1).[3] Paul Revere learnt his craft from his father, Apollos Rivoire (later Paul Revere Sr.), who had been an indentured servant as an apprentice to John Coney. The Reveres owned no slaves. This also appears to be the case with other silversmiths of the period, for example Richard van Dyck (1717-70) and Myers Myers (1723-95), who worked in New York City. The 1703 census is the only record that silversmiths in New York owned slaves. Three of thirteen silversmiths at that time each owned a single female slave, almost certainly a housekeeper. Otherwise, there is no evidence that any New York silversmith ever used slaves in their workshops.[4]

Many silversmiths owned slaves. For example, the probate inventory of Charleston silversmith Thomas You (d. 1786) lists seventeen slaves, but none is said to have been a smith.[5] I am aware only very few instances where it is explicitly stated that slaves were trained silversmiths or goldsmiths (the terms are used interchangeably). One is Abraham, who was owned and trained by the Charleston silversmith Alexander Petrie (d. 1768).[6] It is possible that further information may be found in the account book of Austen and Laurens, slave traders in Charleston, now at Yale.[7] Newport, a goldsmith from Newport, RI, owned and trained by Isaac Anthony, was reported as a runaway in 1749. Four years later, another Newport smith, advertised in a Boston newspaper that he wishes to sell an unnamed goldsmith, possibly the same Newport, but probably not.[8]

[1] K. W. Bruwelheide et al., “Restoring identity to people and place: Reanalysis of human skeletal remains from a cemetery at Catoctin Furnace, Maryland,” Historical Archaeology 54 (2020), 110-37.

[2] C. W. Bishir, Crafting Lives. African American artisans in North Bern, North Carolina (Chapel Hill, NC: UNC Press, 2013); G. Adamson, Craft: An American History (London and New York: Bloomsbury, 2021). For the portrait of Revere, by John Singleton Copley, see: https://collections.mfa.org/objects/32401

[3] Yale Art Gallery has many pieces of silver fashioned by Revere, including a silver teapot made in 1795 (1930-959).

[4] K. Hillen McKinsey, New York City Silversmiths and their Patrons, 1687-1750, Unpublished dissertation, University of Delaware 1984. We cannot be so certain that they did not have indentured servants – workers who were contracted to provide unpaid labor for a period of time, usually five to seven years, in payment of a debt – since this form of servitude was so very common among early immigrants. Debt bondage was usually related to the cost of their passage to North America.

[5] H. Nowell Brazier, “The most elegant and general assortment of plate:” The market for imported and locally-made sterling silver, consumer activism, and national identity in Charleston, 1760–1790, Unpublished dissertation, University of South Carolina, 2009, 31-2.

[6] B. S. Culp, “Mr. Petrie’s ‘Shop on the Bay’,” Antiques and Fine Art (2007), 250-5.

[7] Yale University, Beinecke Library: GEN MSS VOL 184 (folio)

[8] Yale University databases: https://slavery.yale.edu/links/subscription-databases