In our last post, we were introduced by St. Augustine to the practices of fourth- and fifth-century Roman silversmiths. Augustine compares argentarii to pagan gods, who are all great at one thing. He would have preferred a single perfect artisan, competent in all areas. Let us now consider the production of a single object, created by many artisans during Augustine’s lifetime (CE 350-430).[1]

The object we have chosen is a situla, literally a bucket, in this case a small pale, surely a finger pot for washing hands at the dinner table. It is around nine inches (23cm) high. We have chosen it because there has been an excellent recent analysis of it, and objects with which it was found. It is part of a large hoard of silver, the Seuso Treasure – mainly highly decorated plates, jugs, and dishes – now displayed at the Hungarian National Museum, Budapest. This analysis allows us to make the observations that follow.

There are, in fact, two situlae showing complementary scenes from the story of Hippolytus and Phaedra. The situla we have chosen, Hippolytus situla B, comprises several elements, all of which required expert smithing.

Let us posit the following process of production: Silver was melted down, either from ingots or, far more likely, existing objects and coins were recycled; two silver sheets was formed by pouring the molten silver into a mould; a smooth inner liner, and the outer shell of the piece were formed from these sheets of silver by a vascularius. The inner liner was set aside, and the outer shell was then given its exquisite chasing, the scenes of Hippolytus and Phaedra, by a caelator. A flaturarius formed the lower and upper framing bands, the base, and perhaps the beaded rim. However, the beaded rim may have been made elsewhere since, as we shall see, it has a somewhat different silver content. In any event, it was formed with a punch. A crustarius formed the three feet in the form of gryphons, the two decorative handle ornaments, which are busts of emperors, and probably also the lozenged handle. This was done using the lost wax casting technique. The various elements – inner liner, outer shell, handle, feet, etc. – were soldered together. An inaurator then added gilding, including the golden sheen on the figures’ clothes, hair, and other features of the landscape, the bands at the base and upper rim. Finally a tritor buffed it to a high sheen.[2]

Each of these silver-workers worked in an atelier that was, let us imagine – excavations suggest we would not be far not wrong – hot, full of fumes, and had poor ventilation. The melting of metals released various toxins into this workshop, while other escaped through chimneys, spreading across the broader city, its hinterland, and many miles beyond. Silver itself is relatively benign. Repeated exposure to silver particles causes the skin and body tissues to turn grey or blue-grey, a condition known as “argyria.” Ingesting high levels of silver may cause the heart to enlarge and stomach irritation, and breathing in silver particles causes throat and lung irritation. Copper was added to a great deal of Roman silver plate, to improve its mechanical properties. That is, adding copper makes the silver harder, more durable, and easier to work mechanically (i.e. with a hammer, rather than casting). Today we know the silver-copper alloy as sterling silver (typically 92.5% silver, 7.5% copper).

XRF analysis of the Seuso situla shows that the body, handle and feet all contains between 2% and 3% copper, compared to around 95% silver. However, the upper beaded rim, has much less copper, no more than 0.5%, with 99% silver. This tells us that molten copper was added to the silver after it was refined to ensure it was better able to withstand hammering, shaping and chasing. Exposure to copper fumes “causes upper respiratory tract irritation, metallic taste, nausea, and metal fume fever.”[3]

The same XRF analysis shows that each piece of the situla contains very small amounts of lead, between 0.2 and 0.5%. All Roman silver contains lead, usually between 0.5 and 1%. It took a little effort to refine silver to that standard, by a process known as cupellation. It took a great deal more to refine it still further. Evidently, the silver in this situla was refined again to produce very high quality silver before the right amount of copper was added. This may have been done using a process known as liquation, whereby silver is melted together with lead, forming a lead-silver alloy that separates from other metals, including copper. This alloy is then subjected to further cupellation. Roman silver production, including recycling, always involved a great deal of lead. Melting lead releases lead aerosols that are highly toxic.[4]

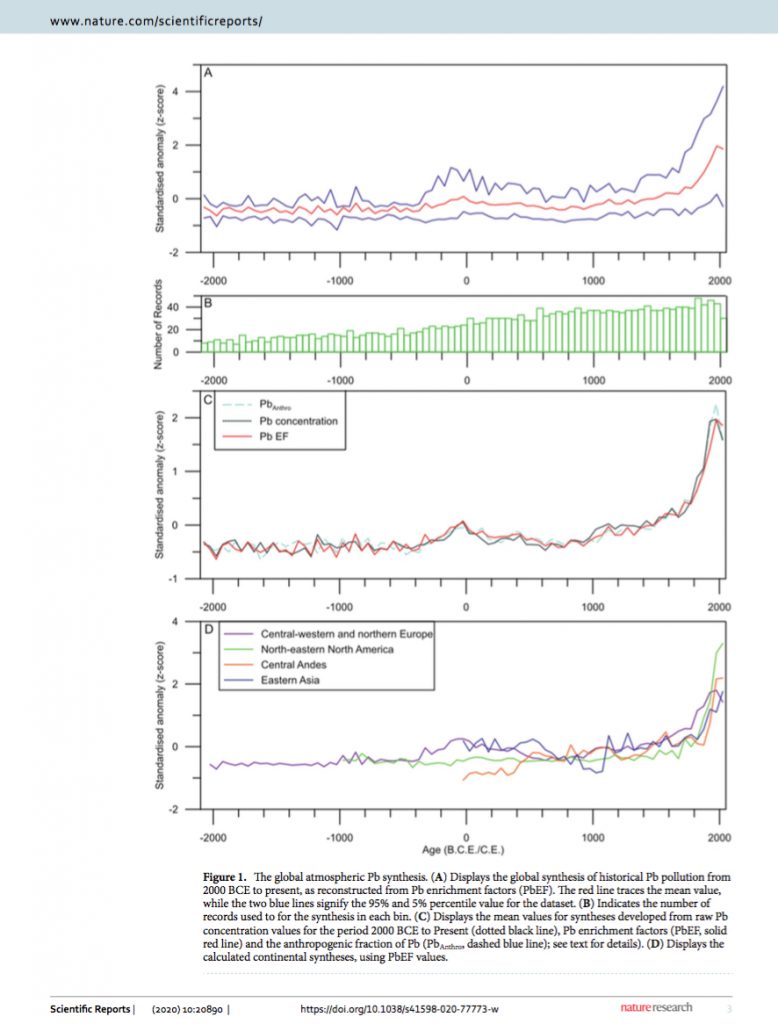

There was, however, something even worse than lead in the workshop, and its immediate vicinity: Mercury. The XRF analysis has identified mercury in the thin layer of gold applied by the gilder. This proves he used a method known as fire gilding, whereby liquid mercury is mixed with gold and then heated, releasing the mercury into the atmosphere and adhering the gold. Mercury is a powerful neurotoxin, ultimately deadly to the fire-gilder. It is “toxic to the central and peripheral nervous systems. The inhalation of mercury vapour can produce harmful effects on the nervous, digestive and immune systems, lungs and kidneys, and may be fatal.”[5] Like lead aerosols, mercury was carried away by the wind and deposited by rain, contaminating the soil and vegetation many miles from its source. A recent study of Roman age skeletons in Spain, over a 70-year period, consistently had more than twice as much mercury and lead as bones of those who lived in the same place afterwards.[6] There is no indication that these were metalworkers. Rather, abundant evidence makes it clear that Roman-age metallurgy had a massive deleterious effect on human health and the environment.[7]

[1] The choice of the Seuso situla was entirely due to the excellent new publication: V. Mozgai et al., “Non-destructive handheld XRF study of archaeological composite silver objects – the case study of the late Roman Seuso Treasure,” Archaeological and Anthropological Sciences 13:83 (2021), 20 pages.

[2] D. E. Strong, Greek and Roman Gold and Silver Plate (Ithaca, NY: Cornell University Press, 1966), 7, 14-16. On silver beaded rims see Richard Hobbs and Laura Perucchetti, “Beaded rims on silver plate vessels in late Roman Britain and beyond,” Britannia 53 (2022), 385-401.

For an instructive video on the creation of a Roman silver cup:

[3] CDC: https://www.cdc.gov/niosh/idlh/1317380.html

[4] Very generally, see Paul Stephenson, “Ancient Roman Pollution,” Lapham’s Quarterly, February 23, 2022.

[5] The approach to this sad fact to date is captured in a sentence by a scholar of silver-smithing: “[Fire-gilding] is a durable and economical use of gold, and the health hazards of mercury were not given the consideration that they are today.” See The Hoxne Late Roman Treasure: Gold Jewellery and Silver Plate, ed. Catherine Johns (London: British Museum Press, 2010), 186.

[6] O. López-Costas et al., “Human bones tell the story of atmospheric mercury and lead exposure at the edge of the Roman world,” Science of the Total Environment 710 (2020), 136319 (7 pages). Here bones from two adjacent cemeteries at A Lanzada in northwestern Spain showed that Romans (first to fifth centuries CE) absorbed twice as much lead and mercury as those who came later (fifth to seventh centuries). Isotopic analysis suggests that 70- 80% of this came from atmospheric lead pollution (and the remainder from local geogenic lead sources).

[7] J. Montgomery et al., ‘“Gleaming white and deadly”: using lead to track human exposure and geographic origins in the Roman period in Britain’, Journal of Roman Archaeology, supplementary series, 78 (2010), 199-226, at 209: “From the 1st c. A.D., some individuals exhibit enamel lead concentrations of up to 30 mg kg-1. These individuals have a level of lead that is 10,000 times higher than that of the least polluted individual in this study: the Early Bronze Age skeleton from Gristhorpe (Yorkshire) (3 μg kg-1; Table 11.3). According to the ratio above, an enamel lead concentration of 30 mg kg-1 would arise from a blood lead level of c.300 μg dL-1, which is far higher than the ~100 μg dL-1 associated with “very severe poisonings”. J. Moore et al., ‘Death Metal: Evidence for the impact of lead poisoning on childhood health within the Roman empire’, International Journal of Osteoarchaeology 31 (2021), 846-56: “This study includes 173 individuals (66 adults and 107 non-adults) from five sites, AD 1st–4th centuries, located throughout the Roman Empire. Results show a negative correlation between age-at-death and core tooth enamel lead concentrations.

This is the third and last of three posts that formed part of a short lunchtime lecture delivered at the Humanities Institute, Pennsylavania State University, in February 2023.